CNC punching & Folding

With the latest and up to date machinery and tooling we have the ability to fabricate a wide range of products.

Our capability means we have the flexibility to manufacture batch orders as well as individual bespoke projects.

Our fully automated punch press and press brake gives our customers the quick turnaround they demand as well as consistent quality.

Sheet metal profiling

Punch profiling sheet metal is potentially a faster and cheaper method than laser cutting, depending on part complexity and batch size. Simpler profiles and larger volumes are ideally suited to punching. An additional benefit is that punching machines can generate simple formed features such as dimples, louvres, logo indentations and knock-outs, thus avoiding the need for additional operations.

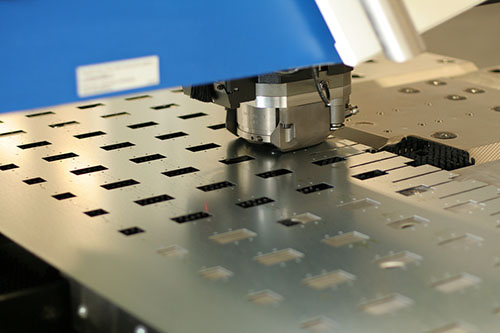

CNC punching

Hillview Engineering's CNC punching machines are capable of punching materials in thicknesses up to 6mm and sheet sizes up to 3 metres x 1.5 metres. The materials punch profiled include stainless steel, mild steel, aluminium, brass, copper and plastics. Using computer-assisted part nesting allows maximum material utilisation. The punching head also allows simple forming and tapping (threading) operations to be carried out during the same cycle, therefore saving the need for setting up secondary operations

Our products are used extensively across a wide range of applications including

Automotive/Engineering: Classic cars, motorbikes and trailers, including heat shields, tanks, brackets, boxes and guards. Spool holders, turbine holders, rings and frames.

Farming and Horses: Stables, doors, rails, security fencing and guards. Stainless steel Veterinary equipment and kennels

Catering/Hospitality: Kitchen worktops, Catering and food equipment, splashbacks, cooker hoods, flu-liners, shelving, window sills, and drain covers. As well as bespoke chandeliers, stools, tables and garden containers.

Construction & Renovation: Church spire rings and window frames.

Retail Premises: Shop signs. Copper and brass sheet work, frames and sills. Stainless steel wall cladding. Pub refits. Stainless steel furniture

HILLVIEW engineering Ltd

HILLVIEW engineering Ltd